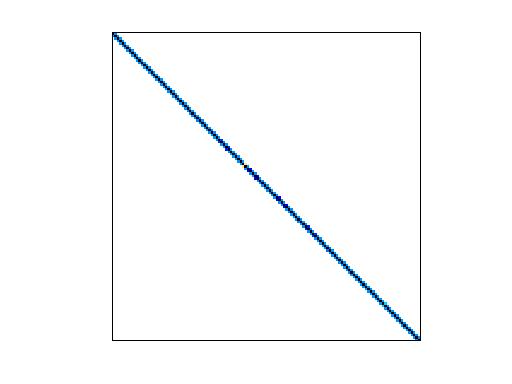

GHS_psdef/s3dkt3m2

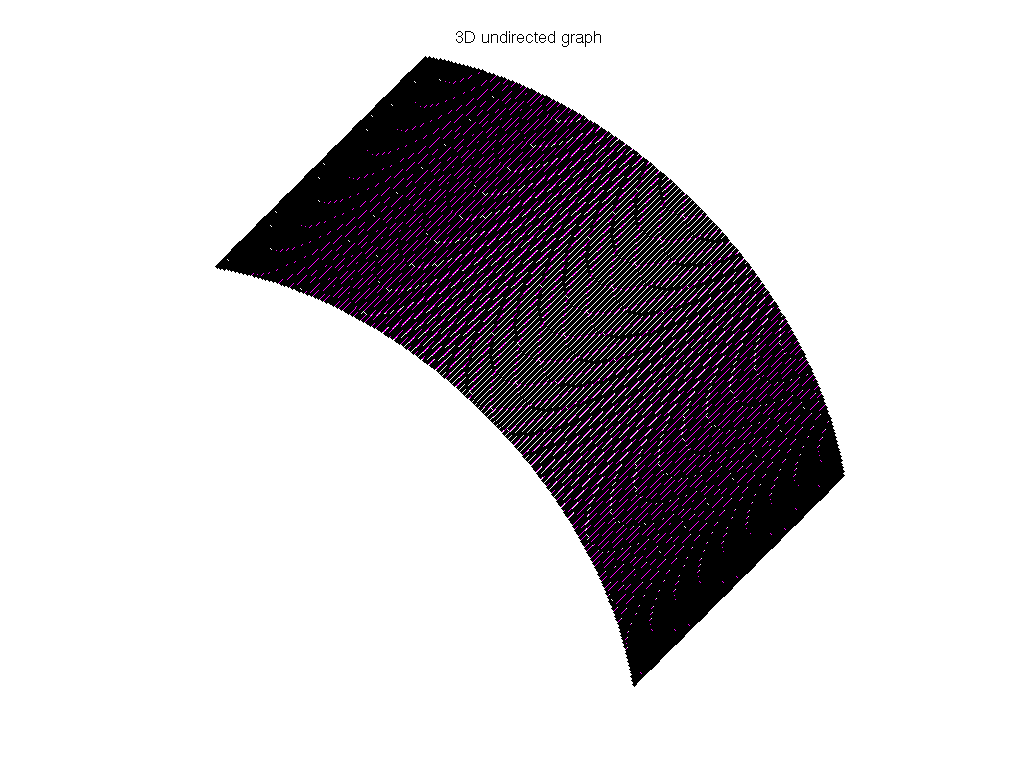

FEM, cylindrical shell, 150x100 tri. mesh, R/t=1000

| Name |

s3dkt3m2 |

| Group |

GHS_psdef |

| Matrix ID |

1276 |

|

Num Rows

|

90,449 |

|

Num Cols

|

90,449 |

|

Nonzeros

|

3,686,223 |

|

Pattern Entries

|

3,753,461 |

|

Kind

|

Structural Problem |

|

Symmetric

|

Yes |

|

Date

|

1997 |

|

Author

|

R. Kouhia |

|

Editor

|

R. Boisvert, R. Pozo, K. Remington, B. Miller, R. Lipman, R. Barrett, J. Dongarra |

| Structural Rank |

90,449 |

| Structural Rank Full |

true |

|

Num Dmperm Blocks

|

1 |

|

Strongly Connect Components

|

1 |

|

Num Explicit Zeros

|

67,238 |

|

Pattern Symmetry

|

100% |

|

Numeric Symmetry

|

100% |

|

Cholesky Candidate

|

yes |

|

Positive Definite

|

yes |

|

Type

|

real |

| Download |

MATLAB

Rutherford Boeing

Matrix Market

|

| Notes |

%

%FILE s3dkt3m2.mtx

%TITLE Cyl shell R/t=1000 unif 150x100 triang mesh DKT elem with drill rot

%KEY s3dkt3m2

%

%

%CONTRIBUTOR Reijo Kouhia (reijo.kouhia@hut.fi)

%

%BEGIN DESCRIPTION

% Matrix from a static analysis of a cylindrical shell

% Radius to thickness ratio R/t = 1000

% Length to radius ratio R/L = 1

% One octant discretized with uniform 150 x 100 triangular mesh

% element:

% facet-type shell element where the bending part is formulated

% using the stabilized MITC theory (stabilization paramater 0.4)

% the membrane part includes drilling rotations using

% the Hughes-Brezzi formulation with (regularizing parameter = G/1000,

% where G is the shear modulus)

% full 3-point integration

% --------------------------------------------------------------------------

% Note:

% The sparsity pattern of the matrix is determined from the element

% connectivity data assuming that the element matrix is full.

% Since this case the material model is linear isotropically elastic

% and the FE mesh is uniform there exist some zeros.

% Since the removal of those zero elements is trivial

% but the reconstruction of the current sparsity

% pattern is impossible from the sparsified structure without any further

% knowledge of the element connectivity, the zeros are retained in this file.

% ---------------------------------------------------------------------------

%END DESCRIPTION

%

%

|